Quality, Hazardous Substance Management Policy

Quality & hazardous substance management policies and objectives

It is hoped that quality demonstrated by PANJIT renders satisfying customers and the satisfaction reaches inside PANJIT, making all employees feel proud working for PANJIT.

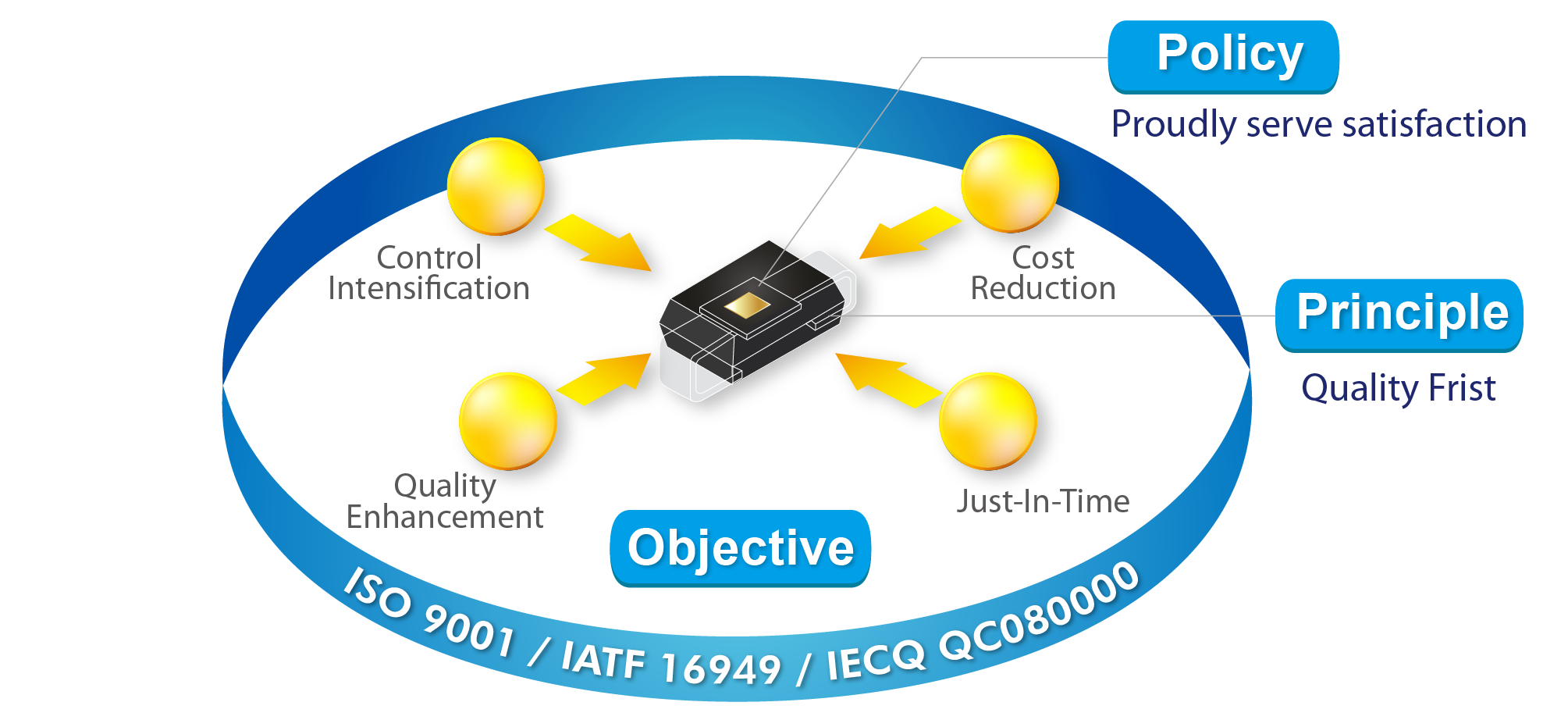

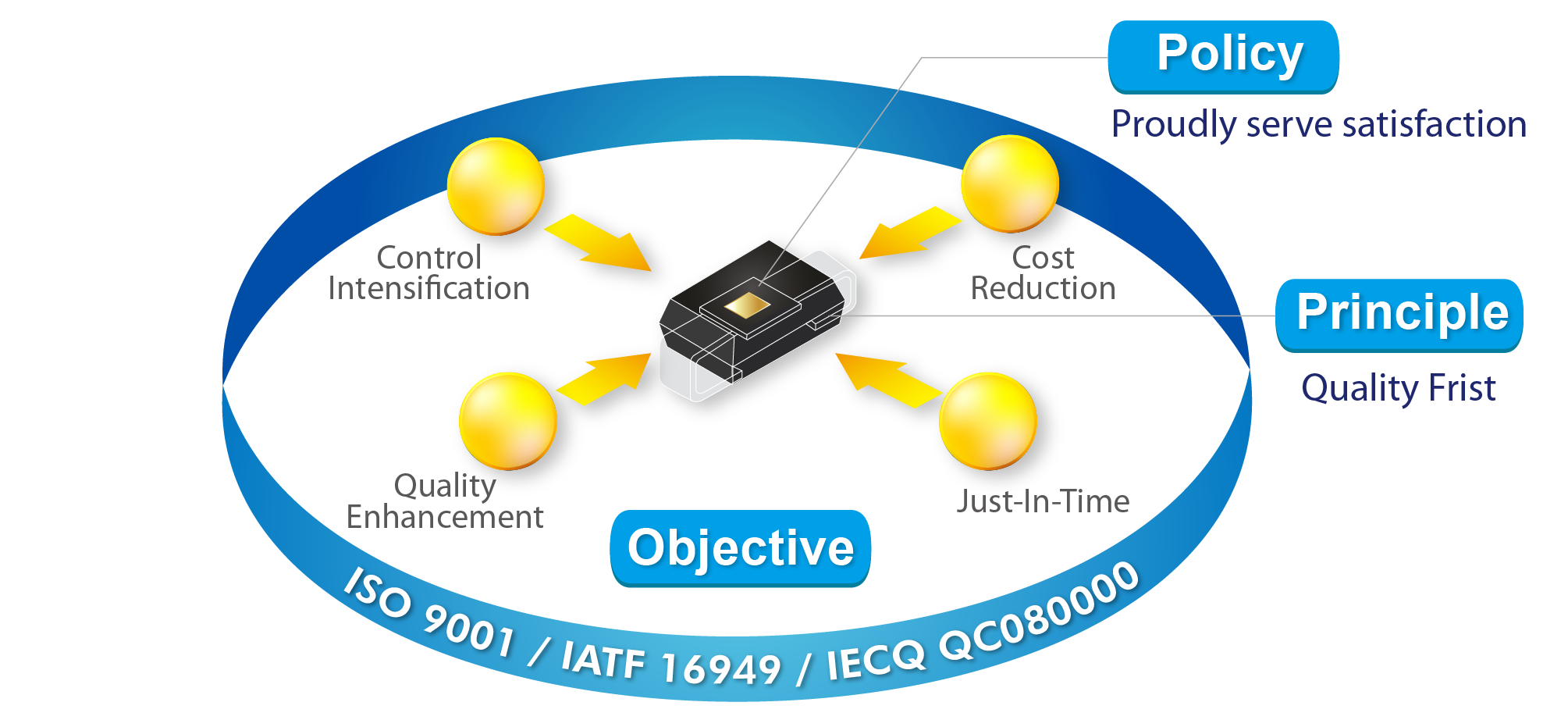

Our quality policy is like the core of our chip; it surrounds the center of the corporation and stacks up the idea of “Quality First.” They are linked to each other. Finally, the compound serves as our quality objective to bind it all together.

The quality policy, quality principle, and quality objective combine and become the product image so that each employee, while handling each product, thinks of the Company’s quality policy, principle, and objective.

✔ Quality policy: Proudly serve satisfaction

✔ Quality principle: Quality First

✔ Quality objective: Control intensification, cost reduction, quality enhancement, and just-in-time

Quality System

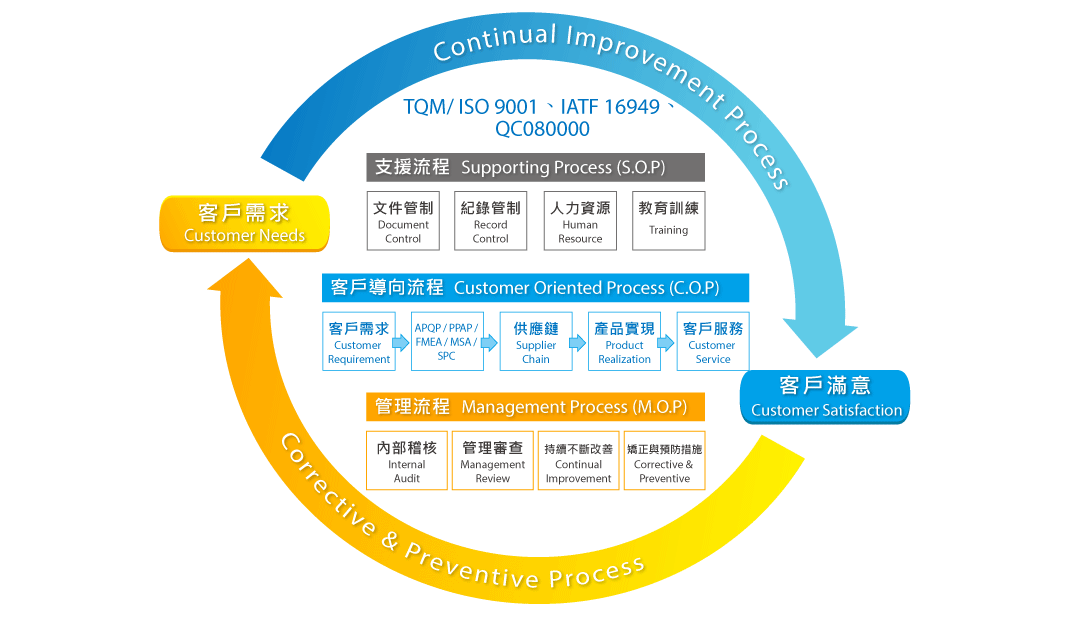

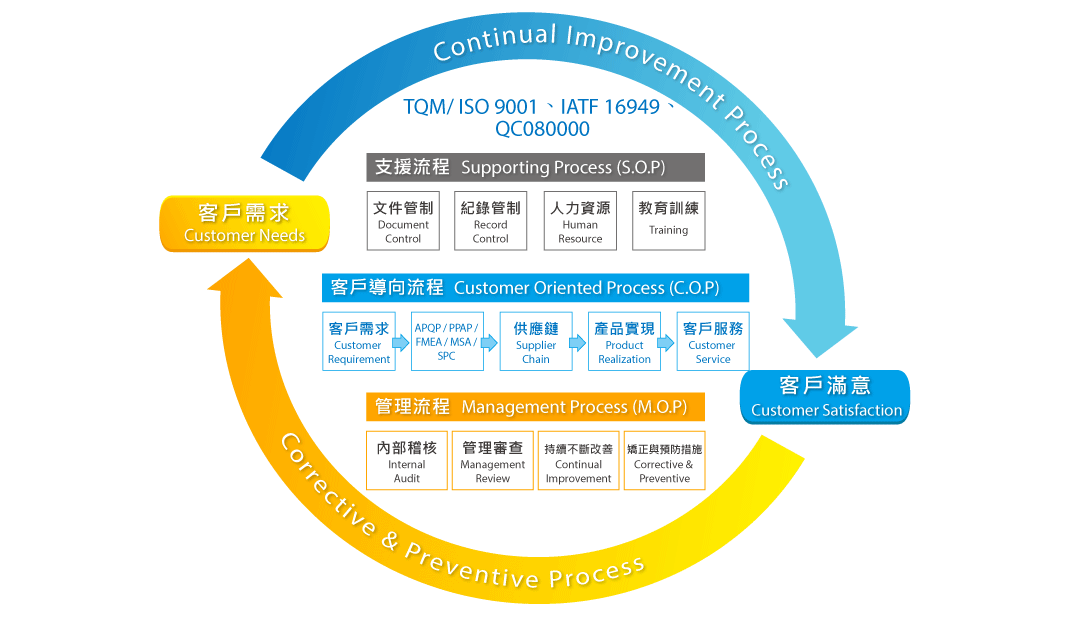

Continual Improvement & Corrective and Preventive Process

The whole company builds on the Total Quality Management (TQM) train of thought and adopts the IATF16949 approach.

We have the customer-oriented process (COP), the support-oriented process (SOP), and the management-oriented process (MOP).

Customer Oriented Process-COP: Both the input and output are processes related to customers. The process starts with customer requirements to fulfill customer needs. It is the focus of the IATF requirements.

Supporting Process-SP: Each main process is accompanied by one or multiple supportive processes. Documentation/record control, human resources, educational training, etc.

Management Process-MP: It is the process where the organizational or quality system is managed, such as internal audits, management review, correction and prevention, continuous improvement, among others.

Quality Milestone

Quality Certification

Green Product Compliance Declaration

REACH

REACH is a European Community Safety Regulation covering the registration, evaluation, authorization and restriction of chemicals. As of June 1, 2007, substances of high concern that are imported into the EU may require authorization. Manufacturers and importers must register with the European Chemicals Agency (ECHA) for goods imported into the EU with an annual import volume of more than 1 ton (including 1 ton). If substances imported into the EU are classified as Substances of Very High Concern (SVHC), they will require authorization. If there is any more than 0.1% of SVHC and the annual import of the substance exceeds 1 ton, the EU manufacturer or importer must notify the European Chemicals Agency (ECHA).

RoHS

RoHS stands for Restriction of Hazardous Substances, and impacts the entire electronics industry and many electrical products as well. The original RoHS, also known as Directive 2002/95/EC, originated in the European Union in 2002 and restricts the use of six hazardous materials found in electrical and electronic products. All applicable products in the EU market since July 1, 2006 must pass RoHS compliance.

Directive 2011/65/EU was published in 2011 by the EU, which is known as RoHS-Recast or RoHS 2. RoHS 2 includes a CE-marking directive, with RoHS compliance now being required for CE marking of products. RoHS 2 also added Categories 8 and 9, and has additional compliance recordkeeping requirements.Directive 2015/863 is known as RoHS 3. RoHS 3 adds four additional restricted substances (phthalates) to the list of six. RoHS 3 Deadline is 22 July 2019.

Conflict-Free

The U.S. Securities and Exchange Commission (SEC), under Section 1502 of the Dodd-Frank Act, requires companies to disclose the sources of conflict minerals used in their products. These minerals may come from regions affected by conflict and human rights abuses. Following OECD’s latest due diligence guidelines, companies must thoroughly review and manage the supply chain of 3TG minerals—including cobalt, tin, tungsten, and gold—and other critical minerals to ensure they do not fuel conflict or violations. These minerals are widely used in ICT products and are integral to global manufacturing and supply chains.